Many people are perplexed by countersink holes (often called sink hole or countersunk hole) on PCB boards. Indeed these terms deserve a good explanation.

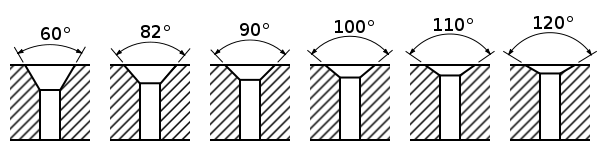

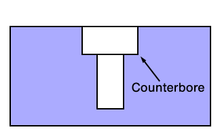

A countersunk hole is simply a normal right cylindrical through-hole with an additional right conical section removed on the top. The cone angle is typically 82 or 100 degrees. A related term is counterbore hole which has an additional flat-bottomed hole. The following are two cross-section diagrams, courtesy of Wikipedia.

On a PCB pad, countersink or counterbore holes can be plated for unplated.

A common usage of countersink or counterbore holes is to allow the head of a countersunk bolt or screw, when placed in the hole, to sit flush with or below the surface of the surrounding material.

Countersink/counterbore holes are commonly used for mounting to ensure the clearance is sufficient where vertical space is very tight. Plated countersink/counterbore holes are also used for chassis ground contact.

In manufacturing pads with countersink/counterbore holes, special precision drilling is required. Many PCB manufacturers do not have the capability drilling countersink/counterbore holes. At MyRO, we have advanced drilling machines which can produce perfect countersink/counterbore holes to your specification.

a place to learn draw a pcb?

here’s…

http://www.youtube.com/watch?v=9_BzrDuDYgU